Especially for those dealing with moisture control, the terms “Desiccant and Deliquescent” are often used. While they both serve the purpose of absorbing moisture, there are distinct differences between the two. This article aims to shed light on the dissimilarities between desiccants and deliquescent materials, highlighting their unique properties, applications, and advantages. By gaining a comprehensive understanding of these differences, you will be better equipped to make informed decisions when it comes to moisture management in your specific industry.

Definition of Desiccant and Deliquescent

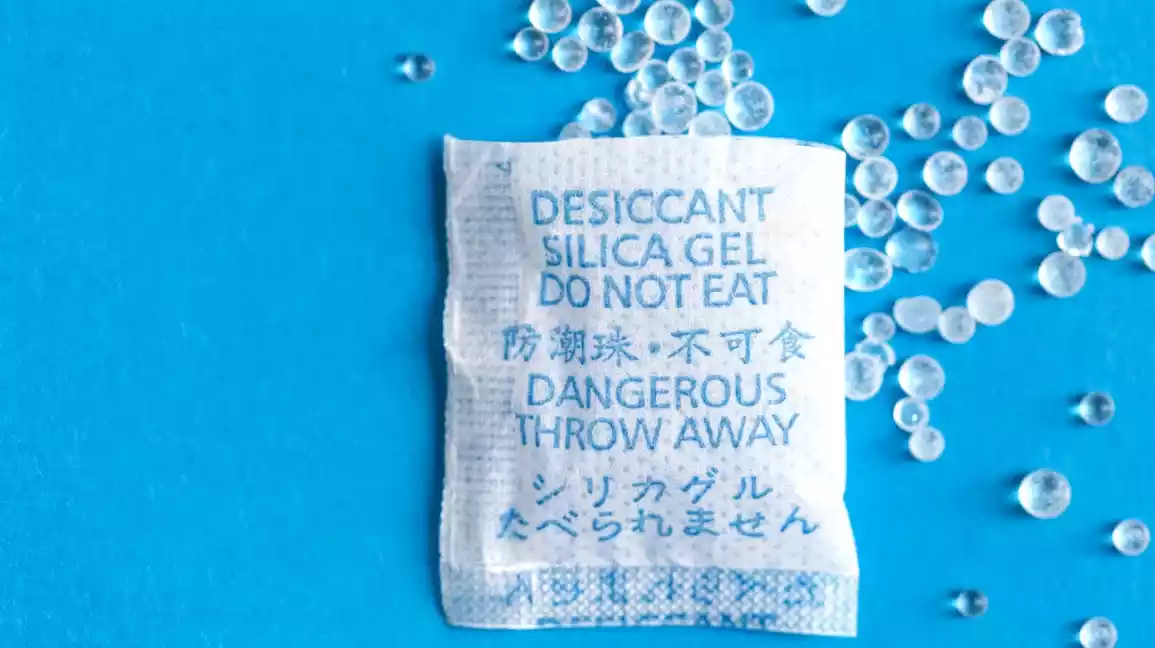

Desiccant: A desiccant refers to a substance or material that can absorb moisture or water vapor from the surrounding environment, thereby reducing humidity levels. Desiccants work by creating a dry environment or by binding moisture to prevent its presence in a given space. They are commonly used in various applications, such as packaging, storage, and industrial processes, to prevent moisture-related damage, corrosion, or degradation of materials.

Deliquescent: Deliquescent substances are hygroscopic materials that can absorb moisture from the air or their surroundings to the point of liquefaction. Unlike desiccants, which only absorb moisture and remain in solid form, deliquescent substances take in moisture and dissolve in the absorbed water, forming a liquid solution. This process is known as deliquescence. Deliquescent substances are often used for humidity control or in applications where it is necessary to create a saturated environment, such as in certain laboratory procedures or for maintaining specific conditions in certain industries.

Importance of understanding the differences between desiccants and deliquescent substances

Understanding the differences between Desiccant and Deliquescent substances is important for several reasons:

1. Moisture control effectiveness: Desiccant and Deliquescent substances have different mechanisms of moisture control. Desiccants absorb moisture without dissolving, while deliquescent substances dissolve in the absorbed water. Understanding these mechanisms helps in selecting the appropriate moisture control method based on the desired level of humidity reduction and the specific application requirements.

2. Material compatibility: Different materials and substances may have varying sensitivities to moisture. Some materials may require a dry environment, while others may require a controlled level of humidity. Knowing the differences between desiccants and deliquescent substances enables appropriate material compatibility assessments, ensuring that the selected moisture control method does not harm or alter the properties of the materials involved.

3. Handling and storage considerations: Desiccant and Deliquescent substances may have different handling and storage requirements. Desiccants are typically solid materials that can be easily handled and stored, while deliquescent substances may require specific precautions due to their liquid or semi-liquid nature. Understanding these differences helps in proper storage, transportation, and handling to maintain their effectiveness and prevent any safety risks.

4. Application suitability: Desiccant and Deliquescent substances are used in various applications, ranging from packaging and storage to industrial processes and laboratory procedures. Understanding the differences between the two allows for the selection of the most suitable moisture control method for a specific application, taking into account factors such as required humidity levels, duration of moisture control, and potential interactions with other substances or materials present in the environment.

5. Long-term effectiveness and maintenance: Desiccant and Deliquescent substances may have different saturation and regeneration processes. Desiccants can often be regenerated by removing the absorbed moisture, while deliquescent substances require disposal or replacement once they have dissolved completely. Understanding these differences helps in managing the long-term effectiveness and maintenance requirements of the chosen moisture control method.

By understanding the differences between Desiccant and Deliquescent substances, individuals and industries can make informed decisions when it comes to selecting the appropriate moisture control method, ensuring optimal performance, material protection, and safety in various applications.

What are Desiccants?

Desiccants are substances or materials that can absorb moisture or water vapor from the surrounding environment. They are commonly used to control and reduce humidity levels to prevent moisture-related damage, corrosion, or degradation of materials.

Desiccants work by creating a dry environment or by binding the moisture molecules to prevent their presence in a given space. They have a high affinity for water molecules, which allows them to effectively absorb moisture and reduce the relative humidity of the surrounding area.

Desiccants can be in various forms, including solid materials, gels, or even liquids. Some common types of desiccants include silica gel, activated carbon, molecular sieves, calcium chloride, and clay desiccants. Each type of desiccant has its absorption capacity and specific applications.

Desiccants find widespread use in numerous industries and applications, such as:

• Packaging: Desiccant packets are often included in product packaging to prevent moisture damage during storage and transportation, particularly for sensitive items like electronics, pharmaceuticals, and food products.

• Storage: Desiccants are used in storage containers, cabinets, or rooms to maintain low humidity levels and protect items like documents, artwork, clothing, and equipment from moisture damage.

• Industrial processes: Desiccants are employed in various industrial processes, such as drying gases, liquids, or solids, or controlling moisture levels in manufacturing environments.

• Electronics: Desiccants are used in electronic devices and equipment to prevent moisture-induced malfunctions and corrosion of sensitive components.

• HVAC systems: Desiccant dehumidifiers are utilized in heating, ventilation, and air conditioning (HVAC) systems to remove excess moisture from the air, ensuring optimal indoor air quality and comfort.

Desiccants play a crucial role in managing moisture and humidity levels to protect materials, maintain product integrity, and prevent moisture-related issues in various settings and industries.

Absorbent properties

Desiccants possess absorbent properties, allowing them to effectively absorb and remove moisture from their surroundings. These properties enable desiccants to control humidity levels and mitigate the harmful effects of moisture.

Here are some key aspects of desiccants’ absorbent properties:

1. Adsorption: Desiccants primarily work through adsorption, which is the process of attracting and holding moisture molecules on their surface. The surface of desiccant materials contains tiny pores or spaces where moisture molecules adhere, preventing them from remaining in the surrounding environment.

2. High moisture absorption capacity: Desiccants have a high affinity for water molecules, allowing them to absorb a significant amount of moisture relative to their weight or volume. The absorption capacity depends on the specific desiccant material and its composition. For instance, silica gel can typically absorb around 30% of its weight in water.

3. Low equilibrium relative humidity (ERH): Desiccants can lower the equilibrium relative humidity of an environment. ERH refers to the moisture content in the air at which the environment is in equilibrium, meaning no net moisture transfer occurs between the desiccant and the air. Desiccants can reduce the ERH to a level where the air becomes drier and less conducive to moisture-related issues.

4. Reversible absorption: Most desiccants can be regenerated and reused by removing the absorbed moisture. This regeneration process allows desiccants to maintain their effectiveness over multiple cycles. The regeneration methods vary depending on the desiccant type and can involve heating, vacuum drying, or exposure to dry air.

5. Selectivity and specificity: Certain desiccants exhibit selectivity towards specific molecules or gases. Molecular sieves are desiccants with precise pore sizes that selectively absorb certain molecules while allowing others to pass through. This selectivity makes them useful in applications where targeted moisture control is required.

The absorbent properties of desiccants make them effective tools for moisture control in various applications, preventing the negative consequences of excess humidity, such as mold growth, corrosion, material degradation, or loss of product quality. By actively absorbing moisture, desiccants help maintain optimal conditions, extend the shelf life of products, and protect sensitive materials and equipment from moisture-related damage.

Non-reactivity with water

Desiccants are known for their non-reactivity with water, meaning they do not chemically react or undergo significant changes when they come into contact with water molecules. This characteristic is crucial in maintaining the effectiveness and stability of desiccants in moisture control applications.

Here’s an explanation of desiccants’ non-reactivity with water:

1. Stability: Desiccants are typically composed of materials that are chemically stable in the presence of water. They are designed to withstand contact with moisture without undergoing significant chemical reactions or degradation. This stability ensures that the desiccant remains functional and does not lose its absorbent properties when exposed to water.

2. No dissolution or solubility: Unlike deliquescent substances that dissolve in absorbed water, desiccants do not dissolve or become soluble in water. They retain their solid or granular form even after absorbing moisture. This lack of solubility is essential in applications where maintaining the desiccant’s physical integrity is important, such as in packaging or storage of sensitive materials.

3. Retained absorption capacity: Desiccants maintain their absorption capacity and effectiveness even after coming into contact with water. They continue to adsorb moisture from the surrounding environment without undergoing any chemical changes that would hinder their moisture absorption properties.

4. Non-reactivity with water vapor: Desiccants are designed to selectively react with water molecules rather than water vapor. Water vapor is the gaseous form of water, and desiccants have a strong affinity for water molecules in the vapor phase. Their non-reactivity with water vapor ensures efficient moisture absorption, helping to control humidity levels and prevent moisture-related issues.

The non-reactivity of desiccants with water is an important characteristic, as it allows them to maintain their functionality and absorption capacity over time. By remaining stable and unaffected by water, desiccants can effectively remove moisture from the surrounding environment without compromising their performance.

What is Deliquescent?

Deliquescent substances are hygroscopic materials that can absorb moisture from the air or their surroundings to the point of liquefaction. Unlike desiccants, which only absorb moisture and remain in solid form, deliquescent substances take in moisture and dissolve in the absorbed water, forming a liquid solution. This process is known as deliquescence.

Key characteristics of deliquescent substances include:

1. Hygroscopic nature: Deliquescent substances have a strong affinity for water molecules and can readily attract and absorb moisture from the air. They can actively draw in water vapor, even in environments with relatively low humidity levels.

2. Moisture absorption and dissolution: As deliquescent substances absorb moisture, they undergo a physical change in which the absorbed water causes them to dissolve and form a liquid solution. This results in the transformation of the solid substance into a liquid or semi-liquid state.

3. Saturation point: Deliquescent substances continue to absorb moisture until they reach their saturation point, at which they are completely dissolved in the absorbed water. The saturation point is the moisture level at which no more moisture can be absorbed, and the substance remains in liquid form.

4. Continuous absorption: Unlike desiccants that reach a saturation point and require regeneration or replacement, deliquescent substances can continuously absorb moisture as long as the surrounding air contains sufficient humidity. They remain in a liquid state as long as moisture is available.

5. Corrosion risks: Deliquescent substances often have corrosive properties due to the formation of corrosive liquid solutions when they dissolve in water. This can pose a risk to certain materials or equipment if not handled properly or if the corrosive liquid comes into direct contact with them.

Deliquescent substances find various applications, including:

• Humidity control: They are used to maintain specific humidity levels in environments where moisture control is critical, such as in laboratories, storage facilities, or industrial processes.

• Chemical reactions: Deliquescent substances can act as reactants or catalysts in certain chemical reactions, taking advantage of their ability to dissolve and provide a medium for chemical transformations.

• Pharmaceuticals and medical applications: Deliquescent substances may be used in pharmaceutical formulations or medical treatments where precise control of moisture content is required.

It’s important to handle and store deliquescent substances properly due to their liquid or semi-liquid nature and the potential for corrosion. Understanding the characteristics and behavior of deliquescent substances helps in effectively managing humidity and moisture-related challenges in specific applications.

Hygroscopic nature

The hygroscopic nature of a substance refers to its ability to readily absorb and retain moisture from the surrounding environment. Hygroscopic substances have a strong affinity for water molecules and can attract and hold moisture even in conditions of relatively low humidity.

Key aspects of the hygroscopic nature of substances include:

1. Water vapor absorption: Hygroscopic substances tend to absorb water vapor directly from the air. They can actively attract and capture water molecules, even in environments with low moisture content.

2. Moisture equilibrium: Hygroscopic substances strive to reach moisture equilibrium with the surrounding environment. This means that they will continue to absorb moisture until they reach a point where the moisture absorbed equals the moisture released, resulting in a balance.

3. Retention of absorbed moisture: Hygroscopic substances can retain the absorbed moisture within their structure or composition. This retention helps maintain the moisture content even when the surrounding air becomes drier.

4. Response to relative humidity: The hygroscopic nature of a substance often causes it to respond to changes in relative humidity. When the humidity increases, the substance absorbs more moisture, and when the humidity decreases, it releases some of the absorbed moisture.

5. Hygroscopicity varies: Different substances exhibit varying degrees of hygroscopicity. Some substances are highly hygroscopic, meaning they can rapidly absorb significant amounts of moisture, while others may have a lower hygroscopicity and absorb moisture at a slower rate.

The hygroscopic nature of substances has several implications and applications, including:

• Humidity control: Hygroscopic materials are used in applications where maintaining specific humidity levels is crucial. They can help control moisture content in storage areas, laboratories, or manufacturing environments.

• Preservation of products: Hygroscopic substances are used to preserve products, such as food items, by preventing moisture absorption and maintaining their quality and shelf life.

• Moisture-sensitive materials: Hygroscopic substances can protect moisture-sensitive materials, such as electronics, pharmaceuticals, or artworks, by absorbing excess moisture that could cause damage or degradation.

• Dehumidification: Some hygroscopic materials are utilized in dehumidification processes, such as in air conditioning systems or moisture-absorbing packets, to remove moisture from the air.

Understanding the hygroscopic nature of substances helps in selecting appropriate materials for specific applications where moisture control, preservation, or protection is required.

Ability to dissolve in absorbed water

The ability of a substance to dissolve in the water it absorbs is a characteristic associated with deliquescent substances. Deliquescent substances have a hygroscopic nature and can absorb moisture from the air or their surroundings, leading to their dissolution in the absorbed water.

Here’s an explanation of their ability to dissolve:

1. Dissolution process: When a deliquescent substance absorbs moisture, the water molecules penetrate its structure and interact with the individual particles or molecules of the substance. As a result, the substance gradually dissolves in the absorbed water, forming a liquid solution.

2. Liquid or semi-liquid state: Once the deliquescent substance fully dissolves in the absorbed water, it transitions into a liquid or semi-liquid state. This is in contrast to desiccants, which typically retain their solid or granular form after absorbing moisture.

3. Saturation point: Deliquescent substances continue to absorb moisture until they reach their saturation point. At this point, the substance is completely dissolved in the absorbed water, and no further moisture absorption occurs. The saturation point depends on the specific deliquescent substance and the conditions of the surrounding environment.

4. Formation of liquid solutions: The dissolution of deliquescent substances in water results in the formation of liquid solutions. These solutions can be corrosive or have specific properties depending on the nature of the dissolved substance. The presence of dissolved substances can have various effects on the properties and behavior of the liquid solution.

5. Continuous absorption and dissolution: Deliquescent substances can continuously absorb moisture as long as the surrounding air contains sufficient humidity. The absorbed water facilitates the dissolution of the substance, maintaining it in a liquid or semi-liquid state and allowing for continuous moisture absorption.

Understanding the ability of deliquescent substances to dissolve in absorbed water is important in applications where moisture control or the creation of a saturated environment is desired. It helps in selecting appropriate materials for specific purposes and managing the effects of dissolved substances on the resulting liquid solution.

Differences Between Desiccant and Deliquescent

Desiccant and Deliquescent substances are two distinct types of moisture control agents with key differences in their properties and behavior.

Here are the main differences between Desiccant and Deliquescent substances:

1. Moisture absorption mechanism: Desiccants absorb moisture through adsorption, which is the process of attracting and holding moisture molecules on their surface. They do not dissolve in the absorbed water. In contrast, deliquescent substances absorb moisture through absorption, which involves the uptake of moisture into the substance and its subsequent dissolution.

2. Physical form: Desiccants are typically solid materials or substances, such as silica gel, activated carbon, or molecular sieves. They maintain their solid or granular form even after absorbing moisture. On the other hand, deliquescent substances can be solid materials or salts that transform into a liquid or semi-liquid state upon absorbing moisture and dissolving in the absorbed water.

3. Saturation and regeneration: Desiccants have a saturation point, beyond which they can no longer absorb moisture. They require regeneration, a process of removing the absorbed moisture or restoring their original moisture-absorbing capacity. Desiccants can often be regenerated and reused. In contrast, deliquescent substances continue to absorb moisture until they reach their saturation point, at which they dissolve completely in the absorbed water. Once dissolved, they cannot be regenerated and usually require disposal or replacement.

4. Reaction with water: Desiccants are non-reactive with water. They do not chemically react or undergo significant changes when they come into contact with water molecules. Deliquescent substances, on the other hand, readily react with water, dissolving and forming a liquid solution. This can result in the formation of corrosive solutions depending on the nature of the dissolved substance.

5. Application range: Desiccants are commonly used in various applications where moisture control and prevention of moisture-related damage are essential, such as packaging, storage, electronics, and industrial processes. Deliquescent substances are often employed when it is necessary to create a saturated environment or to control humidity levels in specific applications, such as certain laboratory procedures or in areas requiring high humidity.

Understanding these differences is important for selecting the appropriate moisture control method based on the desired level of humidity reduction, the specific application requirements, and the potential interactions with materials or substances present in the environment.

Comparison Chart

Here’s a comparison chart highlighting the key differences between Desiccant and Deliquescent substances:

| Factors | Desiccants | Deliquescent Substances |

|---|---|---|

| Moisture Absorption Mechanism | Adsorption: Attracts and holds moisture on the surface | Absorption: Uptake and dissolution in absorbed water |

| Physical Form | Solid or granular | Solid (transforms into liquid/semi-liquid state) |

| Saturation Point | Yes, requires regeneration or replacement | Yes, fully dissolves and cannot be regenerated |

| Reaction with Water | Non-reactive | Reactive, forms corrosive liquid solutions |

| Application Range | General moisture control, prevention of damage | Creation of saturated environments, specific humidity control |

| Duration of Moisture Control | Finite capacity, regeneration, or replacement required | Continuous absorption until saturation |

| Material Compatibility | Generally compatible with a wide range of materials | May react with or damage certain materials |

| Handling and Disposal | Relatively easy to handle, can be regenerated and reused | Liquid/semi-liquid state, cannot be regenerated, disposal may be required |

| Cost-effectiveness | Initial investment, regeneration, or replacement costs | Initial investment, disposal considerations |

| Examples | Silica gel, activated carbon, molecular sieves | Calcium chloride, potassium hydroxide, sodium hydroxide |

This chart provides a summary of the main differences between Desiccant and Deliquescent substances across various factors. It can serve as a helpful reference when deciding which option is more suitable for a specific moisture control application.

Factors to Consider in Choosing Between Desiccants and Deliquescent

When choosing between Desiccant and Deliquescent substances for moisture control, several factors should be considered to determine the most suitable option for a given application.

Here are some key factors to consider:

1. Moisture level and control requirements: Assess the moisture level in the environment or the desired level of humidity control. If the goal is to reduce moisture to a specific level without reaching saturation, desiccants may be the appropriate choice. However, if the aim is to create a saturated or high-humidity environment, deliquescent substances would be more suitable.

2. Duration of moisture control: Consider the duration for which moisture control is required. Desiccants often have a finite capacity and need periodic regeneration or replacement once they reach saturation. Deliquescent substances, on the other hand, can continuously absorb moisture until they are fully dissolved.

3. Material compatibility: Evaluate the compatibility of desiccants or deliquescent substances with the materials or substances present in the environment. Some materials may react or be damaged by the corrosive nature of deliquescent substances. Desiccants are generally non-reactive with materials, making them suitable for a wider range of applications.

4. Handling and disposal considerations: Take into account the handling and disposal requirements associated with each option. Desiccants are typically easy to handle, and many can be regenerated for reuse, reducing waste. Deliquescent substances, once dissolved, cannot be regenerated and may require proper disposal due to their liquid or semi-liquid state.

5. Application-specific requirements: Consider any specific requirements or constraints of the application. If precise moisture control is needed, desiccants with specific adsorption capacities or moisture indicators may be preferred. In cases where a constant high-humidity environment is required, deliquescent substances can provide a continuous source of moisture.

6. Cost-effectiveness: Evaluate the cost-effectiveness of desiccants and deliquescent substances based on factors such as initial investment, maintenance or regeneration costs, and replacement frequency. Consider the expected lifespan and efficiency of each option to determine the most cost-effective solution.

By considering these factors, you can make an informed decision between Desiccant and Deliquescent substances based on the specific moisture control requirements, compatibility, handling considerations, and cost-effectiveness of the application at hand.

Conclusion

Understanding the differences between desiccant and deliquescent materials is essential for effective moisture management in various industries. Desiccants, such as silica gel, molecular sieves, activated charcoal, and clay, work by adsorbing moisture and creating a low-humidity environment. Deliquescent materials, like calcium chloride, absorb moisture until they dissolve, helping to stabilize the humidity at a desired level.

By choosing the appropriate moisture control solution based on your specific requirements, you can protect your products, equipment, and materials from the damaging effects of moisture.