There are various methods and processes employed to remove pollutants and ensure the purification of water. Two commonly used methods are the activated sludge process and the trickling filter process. While both methods aim to achieve similar outcomes, there are distinct differences between the activated sludge and trickling filters in terms of their design, operation, and effectiveness. This article will explore these differences and shed light on the unique aspects of each method.

Importance of biological treatment processes

Biological treatment processes play a crucial role in wastewater treatment and environmental protection.

Here are some key points highlighting the importance of biological treatment processes:

1. Organic Matter Removal: Biological treatment processes are highly effective in removing organic pollutants from wastewater. Through the activity of microorganisms, natural compounds displayed in wastewater are broken down and changed into less complex and more steady shapes, lessening their natural effect.

2. Nutrient Removal: Biological treatment processes also aid in the removal of nutrients, such as nitrogen and phosphorus, from wastewater. Excessive nutrient levels in water bodies can lead to eutrophication, causing harmful algal blooms and oxygen depletion. Biological processes like nitrification and denitrification help convert nitrogen compounds into harmless forms and reduce the nutrient load in the treated effluent.

3. Environmental Protection: By removing organic pollutants and nutrients, biological treatment processes help protect the environment. Treated wastewater that meets stringent quality standards can be safely discharged into receiving waters without causing harm to aquatic life or contaminating drinking water sources.

4. Public Health: Effective wastewater treatment is essential for safeguarding public health. Untreated or ineffectively treated wastewater can contain destructive pathogens, microbes, and infections that posture noteworthy well-being dangers on the off chance that discharged into the environment or utilized for water system purposes. Biological treatment processes, particularly disinfection techniques like chlorination or ultraviolet (UV) irradiation, help eliminate or reduce these pathogens, protecting public health.

5. Compliance with Regulations: Biological treatment processes are designed to meet regulatory standards and discharge limits set by environmental agencies. Compliance with these regulations ensures that wastewater treatment facilities operate within legal boundaries, minimizing pollution and ensuring responsible management of wastewater.

6. Water Reuse and Resource Recovery: Biological treatment processes also enable water reuse and resource recovery. Treated wastewater can be used for non-potable applications such as irrigation, industrial processes, and groundwater recharge. Additionally, valuable resources like energy, nutrients, and biosolids can be recovered from wastewater through advanced biological treatment methods, promoting sustainability and circular economy principles.

7. Sustainable Development: Implementing biological treatment processes aligns with the principles of sustainable development. By viably treating wastewater, lessening contamination, moderating water assets, and recouping profitable assets, these forms contribute to natural, social, and financial maintainability.

Biological treatment processes are essential for wastewater treatment, environmental protection, public health, regulatory compliance, water reuse, and sustainable development. They give viable and proficient implies of lessening poisons, ensuring environments, and guaranteeing the capable administration of wastewater for the good thing about both display and future eras.

Definition of Activated Sludge and Trickling Filter

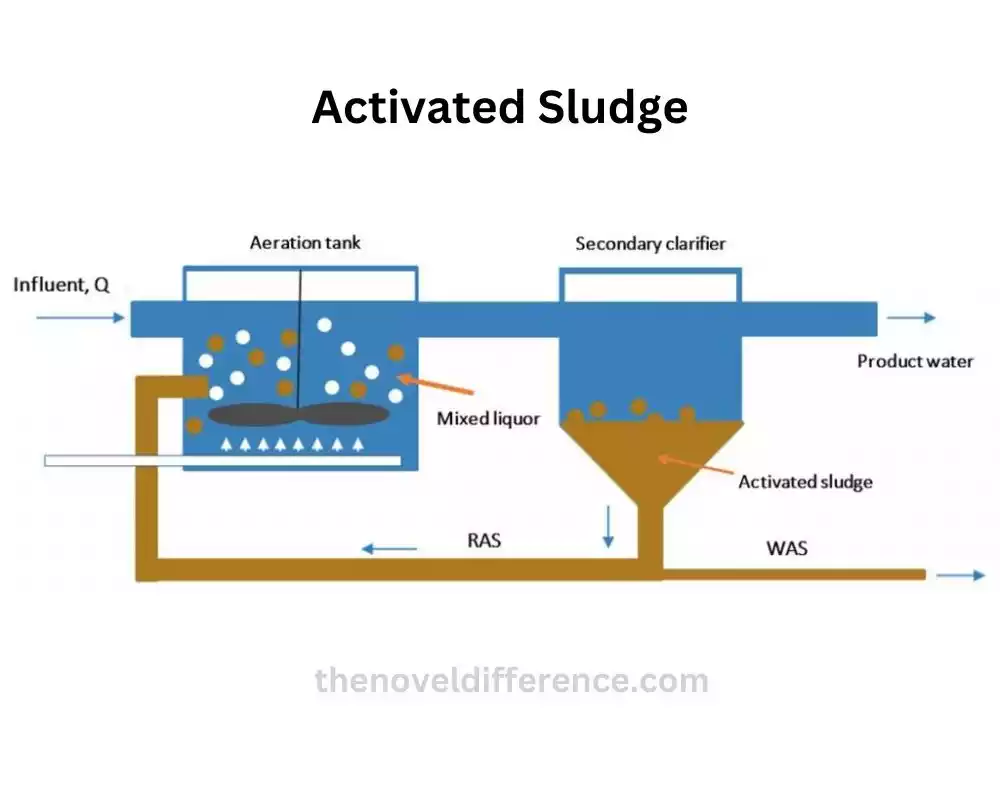

Activated Sludge: Activated sludge is a widely used biological wastewater treatment process that involves the cultivation of a diverse microbial community to treat organic pollutants in wastewater. The process consists of an aeration tank where wastewater is mixed with a suspended growth of microorganisms, known as activated sludge. The microorganisms, counting microbes and protozoa, utilize the natural matter within the wastewater as a nourishment source and break it down through oxygen-consuming breath. This process occurs in the presence of oxygen, which is supplied by diffused air or mechanical agitation in the aeration tank.

After the aerobic treatment, the wastewater and activated sludge mixture is directed to a secondary clarifier, where the sludge settles and is returned to the aeration tank as “return sludge” to maintain an active microbial population. The treated wastewater, known as effluent, is discharged or subjected to further treatment before disposal. Activated sludge processes are known for their high removal efficiency of organic pollutants and their ability to achieve nutrient removal through additional process steps such as biological phosphorus removal or nitrification-denitrification.

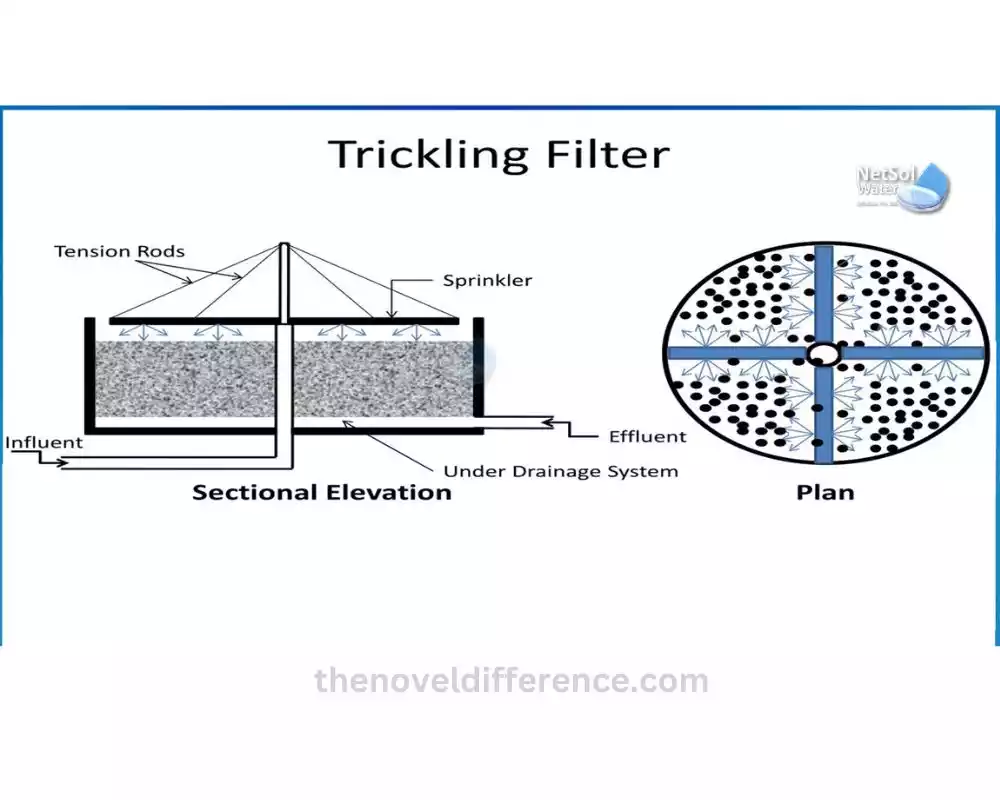

Trickling Filter: A trickling filter is a biological wastewater treatment process that utilizes a bed of solid media, often composed of rocks, gravel, or synthetic materials, to support the growth of a biofilm that facilitates the degradation of organic pollutants in wastewater. Wastewater is distributed over the surface of the media through a distribution system, allowing it to trickle down through the media by gravity or with the help of sprinklers or rotating arms. As the wastewater flows over the media, a thin layer of microorganisms develops on the media surface, forming a biofilm. This biofilm acts as a biological filter, where microorganisms metabolize and break down the organic matter present in the wastewater.

The biofilm’s microbial community, including bacteria, fungi, and algae, provides the necessary metabolic reactions for organic pollutant removal. The treated wastewater, known as effluent, is collected at the bottom of the trickling filter and further treated or discharged. Trickling filters are known for their simplicity, low energy requirements, and ability to handle variations in hydraulic and organic loading. They are particularly effective for the treatment of wastewater with moderate to low organic content.

What is Activated Sludge?

Activated sludge refers to a biological process used in wastewater treatment for the removal of organic pollutants. It involves the cultivation of a mixed population of microorganisms, known as activated sludge, in an aeration tank. The activated sludge consists of a diverse community of bacteria, protozoa, and other microorganisms.

The process begins with the introduction of wastewater into the aeration tank, where air or oxygen is supplied to create aerobic conditions. The microorganisms in the activated sludge metabolize and consume the organic matter present in the wastewater as a food source. This microbial activity leads to the breakdown and decomposition of organic pollutants through biochemical reactions, primarily aerobic respiration.

The aeration tank is typically designed to provide an ideal environment for the microorganisms, including sufficient dissolved oxygen, appropriate temperature, and mixing to ensure contact between the microorganisms and the wastewater. The duration of the wastewater’s residence time in the tank is carefully controlled to allow adequate contact time for effective treatment.

After the wastewater is thoroughly mixed and treated in the aeration tank, it proceeds to a secondary clarifier or settling tank. The mixture of treated wastewater and activated sludge is allowed to settle. The actuated slime settles to the foot of the tank, shaping a slime layer, whereas the clarified water, known as the supernatant or gushing, rises to the beat.

A portion of the settled sludge, called “return sludge,” is recycled back to the aeration tank to maintain an active and healthy microbial population. This helps ensure consistent treatment performance. The excess sludge, also known as waste sludge, is either further treated or removed from the system.

Activated sludge processes are known for their high removal efficiency of organic pollutants, including carbonaceous compounds. They can also be designed to achieve nutrient removals, such as nitrogen and phosphorus, through additional process steps like nitrification-denitrification or biological phosphorus removal. The treated effluent from the activated sludge process can be discharged into receiving waters or subjected to further treatment based on regulatory requirements and specific site conditions.

What is a Trickling Filter?

A trickling filter is a biological wastewater treatment process that utilizes a bed of solid media to support the growth of a biofilm that facilitates the degradation of organic pollutants in wastewater.

Here’s a detailed description of the trickling filter process:

1. Wastewater Distribution: The wastewater to be treated is evenly distributed over the surface of a bed of solid media, often made of rocks, gravel, plastic, or other synthetic materials. The distribution can be achieved through various means, including sprinklers, rotating arms, or perforated pipes.

2. Biofilm Formation: As the wastewater trickles down through the media, a thin layer of microorganisms begins to develop on the surface of the media. This layer is called a biofilm and comprises an assorted community of microorganisms, counting microbes, organisms, and green growth. The biofilm provides a surface for microbial attachment and growth.

3. Organic Matter Degradation: The organic pollutants present in the wastewater come into contact with the biofilm as they flow over the media. The microorganisms inside the biofilm metabolize and break down the natural matter through different biochemical responses, counting high-impact and anaerobic forms. The microorganisms use the organic pollutants as a food source, converting them into simpler, less harmful compounds.

4. Oxygen Supply: Oxygen is required for aerobic microbial activity within the biofilm. It can be provided through natural air diffusion or by forced aeration, depending on the design of the trickling filter system. Adequate oxygen supply is crucial to maintain aerobic conditions for effective organic matter degradation.

5. Filtration and Treatment: As the wastewater percolates through the media bed, the biofilm acts as a biological filter, capturing and degrading the organic pollutants present in the wastewater. The media’s porous structure provides surface area for the attachment and growth of microorganisms, allowing for efficient treatment.

6. Effluent Collection: The treated wastewater, known as effluent, is collected at the bottom of the trickling filter system. The effluent typically undergoes further treatment, such as clarification and disinfection, to remove any remaining suspended solids and pathogens before it is discharged or reused.

7. System Monitoring and Control: Trickling filter systems require regular monitoring and control to ensure optimal performance. Parameters such as flow rate, media moisture content, and oxygen supply may be monitored and adjusted as needed to maintain proper treatment efficiency.

Trickling filters are known for their simplicity, low energy requirements, and ability to handle variations in hydraulic and organic loading. The efficiency of the trickling filter process depends on factors such as media type, media depth, wastewater characteristics, and hydraulic loading rates. The treated effluent from the trickling filter process can be discharged into receiving waters or subjected to further treatment based on regulatory requirements and specific site conditions.

Difference Between Activated Sludge and Trickling Filter

Activated Sludge and Trickling Filters are two different biological wastewater treatment processes that have distinct characteristics and operational principles.

Here are the key differences between Activated Sludge and Trickling Filter:

1. Process Configuration:

• Activated Sludge: It involves the cultivation of a mixed population of microorganisms in an aeration tank, where the microorganisms break down organic pollutants in wastewater through aerobic respiration. The process includes aeration and sedimentation tanks.

• Trickling Filter: It utilizes a bed of solid media, such as rocks or plastic, to support the growth of a biofilm that degrades organic pollutants. Wastewater is distributed over the media, allowing the biofilm to treat the wastewater as it trickles down.

2. Biomass:

• Activated Sludge: The biomass consists of suspended microorganisms (activated sludge) in the aeration tank.

• Trickling Filter: The biomass is in the form of a biofilm that develops on the surface of the media.

3. Treatment Mechanism:

• Activated Sludge: Organic matter is treated through the metabolic activity of suspended microorganisms in the aeration tank.

• Trickling Filter: Organic matter is treated through the microbial activity within the biofilm attached to the media.

4. Oxygen Requirement:

• Activated Sludge: Requires continuous and sufficient oxygen supply to support aerobic microbial activity.

• Trickling Filter: Relies on the diffusion of oxygen from the air or forced aeration to provide oxygen for aerobic microbial activity within the biofilm.

5. Contact Time:

• Activated Sludge: The wastewater and microorganisms have an extended contact time in the aeration tank to facilitate organic matter degradation.

• Trickling Filter: The contact time between the wastewater and biofilm is relatively shorter as the wastewater trickles down through the media.

6. Applicability:

• Activated Sludge: Suitable for treating a wide range of wastewater types, including those with high organic loads and nutrient requirements.

• Trickling Filter: More effective for wastewater with moderate to low organic loads and limited nutrient removal needs.

7. System Complexity:

• Activated Sludge: Generally more complex in terms of system design, control, and operation due to the need for aeration and sludge management.

• Trickling Filter: Relatively simpler in terms of system design and operation, requiring less energy and maintenance.

8. Sludge Production:

• Activated Sludge: Produces excess sludge that needs to be managed, which requires additional treatment and disposal.

• Trickling Filter: Produces less sludge compared to activated sludge processes, reducing the sludge management requirements.

9. Land Requirement:

• Activated Sludge: Requires a larger land area for aeration tanks, secondary clarifiers, and sludge handling facilities.

• Trickling Filter: Requires a smaller land area for the media bed and distribution system.

It’s important to note that the selection of the appropriate treatment process depends on various factors, including wastewater characteristics, treatment objectives, site constraints, and regulatory requirements. Both Activated Sludge and Trickling Filters have their advantages and limitations, and the choice between them is based on specific project considerations.

Case Studies and Examples

Sure! Here are a few case studies and examples that highlight the application of Activated Sludge and Trickling Filters in wastewater treatment:

1. Activated Sludge Case Study: Deer Island Wastewater Treatment Plant, Boston, USA

• The Deer Island Wastewater Treatment Plant in Boston, Massachusetts, is one of the largest activated sludge treatment facilities in the United States.

• The plant utilizes the activated sludge process to treat an average daily flow of 380 million gallons of wastewater.

• It incorporates advanced treatment technologies, including nitrification and denitrification processes, to achieve stringent effluent quality standards.

• The plant plays a crucial role in protecting the water quality of Boston Harbor and has significantly improved the environmental conditions of the area.

2. Trickling Filter Case Study: Glasgow Wastewater Treatment Works, Scotland

• The Glasgow Wastewater Treatment Works, located in Dalmarnock, Glasgow, Scotland, incorporates trickling filter technology for wastewater treatment.

• The treatment plant utilizes a combination of trickling filters and activated sludge processes to treat wastewater from the surrounding areas.

• The trickling filters provide primary treatment by removing a significant portion of the organic matter, while the activated sludge process further enhances the treatment efficiency.

• The plant can treat approximately 200 million liters of wastewater per day and plays a crucial role in safeguarding the River Clyde and the environment.

3. Combined Activated Sludge and Trickling Filter Case Study: Kigali Wastewater Treatment Plant, Rwanda

• The Kigali Wastewater Treatment Plant in Rwanda employs a combination of activated sludge and trickling filter processes for efficient wastewater treatment.

• The plant treats wastewater generated from Kigali, the capital city of Rwanda, and surrounding areas.

• The activated sludge process is utilized for primary treatment, followed by trickling filters for further organic matter removal and polishing.

• The treated effluent is discharged into the Nyabarongo River, contributing to the improvement of water quality and environmental sustainability in the region.

These case studies demonstrate the successful application of both activated sludge and trickling filter processes in diverse wastewater treatment scenarios. They highlight the effectiveness of these processes in achieving high-quality effluent and environmental protection goals. It’s important to note that case studies can change depending on site-specific conditions, administrative necessities, and the particular plan and operational parameters of each treatment office.

Conclusion

The choice between the activated sludge and trickling filters for wastewater treatment depends on factors such as treatment efficiency requirements, energy considerations, space availability, and odor control needs. Activated sludge systems offer high treatment efficiency but require aeration and higher energy consumption. Trickling filters, while generally less efficient, have lower energy requirements and reduced odor potential. Both processes play a vital role in the sustainable management of wastewater, and their selection should be based on a thorough analysis of the specific project requirements.