Polymers play a significant part in various businesses, extending from bundling and materials to gadgets and pharmaceuticals. They are flexible materials with a wide run of properties and applications. When talking about polymers, it’s vital to get the qualification between monodisperse and polydisperse polymers. We’ll investigate the contrasts between these two sorts and their suggestions in different areas.

Definition of Monodisperse and Polydisperse Polymers

Monodisperse Polymers: Monodisperse polymers allude to a lesson of polymers where the polymer chains have a contract and uniform conveyance of atomic weights. The polymer chains in a monodisperse polymer sample have very similar sizes and lengths. The term “monodisperse” is determined from the Latin word “manus,” meaning single, and “disperser,” meaning diffuse.

Polydisperse Polymers: Polydisperse polymers, on the other hand, are characterized by a wide run of atomic weights inside the polymer test. The term “polydisperse” is derived from the Latin word “poly,” meaning many, and “disperser,” meaning to scatter. In polydisperse polymers, the polymer chains vary in length, resulting in a distribution of molecular weights, with some chains being shorter and others longer.

The distinction between monodisperse and polydisperse polymers lies in the uniformity or heterogeneity of the molecular weight distribution within the polymer sample. Monodisperse polymers have a contract dispersion, with little variety in chain lengths, whereas polydisperse polymers show a broader conveyance, with a noteworthy run of chain lengths.

Importance of understanding polymer properties

Understanding polymer properties is of utmost importance in various scientific, industrial, and technological fields.

Here are several reasons why understanding polymer properties is significant:

1. Material Design and Development: Polymer properties play a crucial role in designing and developing new materials with desired characteristics. By understanding polymer properties such as mechanical quality, warm steadiness, adaptability, electrical conductivity, and optical properties, analysts and engineers can tailor polymers to meet particular application prerequisites.

2. Performance Optimization: Knowledge of polymer properties allows for optimizing the performance of polymer-based products. By controlling parameters such as atomic weight, atomic structure, and composition, it gets to be conceivable to improve properties like ductile quality, affect resistance, warm resistance, chemical resistance, and surface properties. This optimization leads to improved product performance and reliability.

3. Manufacturing Processes: Understanding polymer properties helps in selecting appropriate manufacturing processes. Different polymers exhibit diverse behaviors during processing, such as melting, flow, and solidification. By considering properties like melt viscosity, glass transition temperature, and crystallization behavior, manufacturers can determine suitable processing techniques like injection molding, extrusion, blow molding, or casting, ensuring efficient and high-quality production.

4. Product Quality Control: Polymer properties are vital for quality control and consistency in manufacturing. Accurate characterization and measurement of properties such as molecular weight distribution, thermal properties, and rheological behavior enable manufacturers to maintain consistent product quality, troubleshoot issues, and ensure compliance with specifications and standards.

5. Applications and Performance Prediction: Understanding polymer properties allows for predicting the performance and behavior of polymers in various applications. For instance, in fields like automotive, aerospace, electronics, packaging, healthcare, and renewable energy, knowledge of polymer properties helps in selecting the most suitable materials for specific applications, ensuring durability, reliability, and safety.

6. Research and Innovation: Polymer properties serve as a foundation for further research and innovation. Exploring the relationships between polymer structure, properties, and performance opens avenues for developing novel polymers with enhanced characteristics, addressing emerging challenges, and advancing fields like nanotechnology, biotechnology, sustainable materials, and advanced composites.

Understanding polymer properties is vital for material design, performance optimization, manufacturing processes, quality control, application suitability, and driving innovation in various industries. It empowers researchers, engineers, and producers to saddle the total potential of polymers and create custom-fitted arrangements to meet the advancing needs of society.

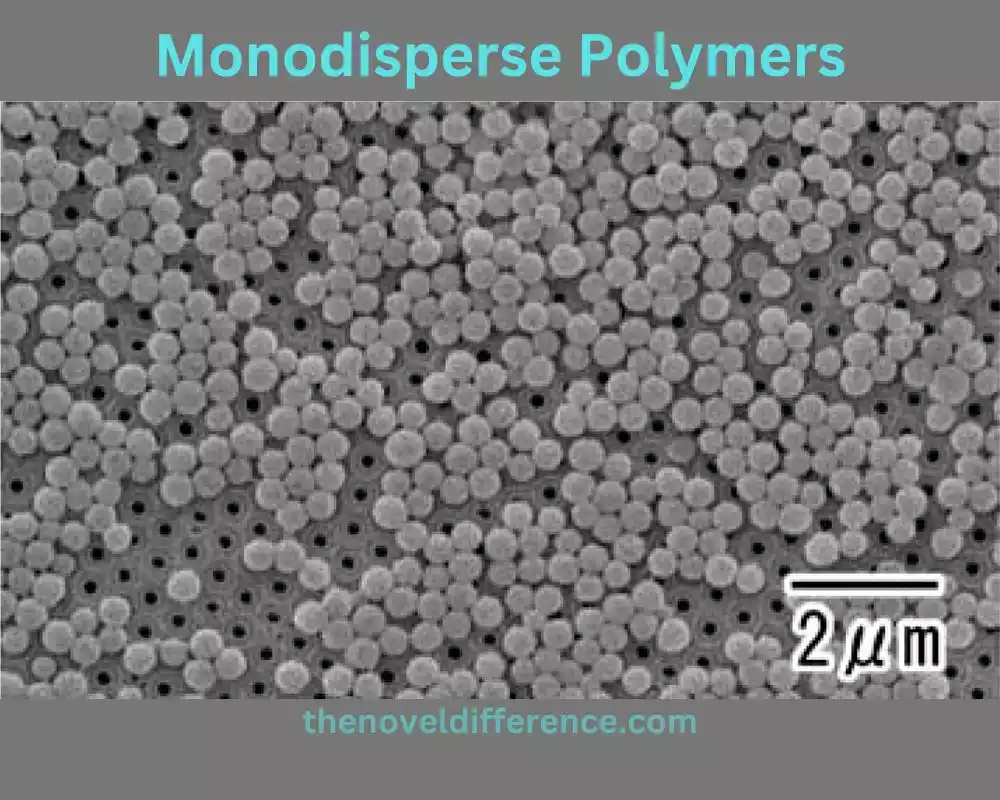

What is Monodisperse Polymers?

Monodisperse polymers, too known as monodisperse macromolecules, are a particular sort of polymer in which the constituent polymer chains have a contract and uniform conveyance of atomic weights. The sizes and lengths of the polymer chains in a monodisperse polymer test are exceptionally comparable to each other.

The majority of polymer chains have nearly identical molecular weights, with minimal variation. This uniformity in molecular weight distribution is achieved through specialized synthesis techniques and precise control over the polymerization process.

Monodisperse polymers offer several distinct advantages over their polydisperse counterparts, which have a broader range of molecular weights.

These advantages include:

1. Enhanced Control: Monodisperse polymers provide precise control over the size, shape, and properties of individual polymer chains. This control allows for a more systematic study of structure-property relationships and facilitates the design of polymers with specific functionalities.

2. Simplified Characterization: The uniformity of molecular weights in monodisperse polymers simplifies their characterization. It empowers more precise and dependable estimations of properties such as consistency, warm behavior, mechanical properties, and self-assembly characteristics.

3. Improved Performance: Monodisperse polymers often exhibit improved performance in specific applications compared to polydisperse polymers. The uniformity of chain lengths can lead to enhanced mechanical strength, more predictable processing behavior, and improved control over material properties.

4. Versatile Applications: Monodisperse polymers find applications in various fields, including nanotechnology, drug delivery systems, coatings, electronics, and biomaterials. Their uniformity allows for better integration and compatibility with other materials and facilitates precise control over the final product’s properties.

It is important to note that achieving perfect monodispersity in polymers is often challenging, and there may still be slight variations in molecular weights in practice.

The term “monodisperse” generally refers to polymers with a significantly narrower molecular weight distribution compared to their polydisperse counterparts.

Monodisperse polymers play a crucial role in advancing polymer science, materials research, and technological applications by providing controlled and uniform macromolecular structures.

Manufacturing processes and techniques

Manufacturing monodisperse polymers require specialized techniques to achieve a narrow and uniform distribution of molecular weights.

Here are some commonly employed manufacturing processes and techniques for monodisperse polymers:

1. Controlled/Living Polymerization: Controlled polymerization techniques allow for precise control over the polymerization process, resulting in monodisperse polymers.

Examples of controlled polymerization methods include:

a. Atom Transfer Radical Polymerization (ATRP): ATRP utilizes a combination of a transition metal catalyst, a halogen-containing initiator, and a reducing agent to control the polymerization. It enables the synthesis of monodisperse polymers with controlled molecular weights.

b. Reversible Addition-Fragmentation Chain Transfer Polymerization (RAFT): RAFT polymerization involves a reversible chain transfer agent that controls the polymer growth and allows for the synthesis of monodisperse polymers.

c. Nitroxide-Mediated Polymerization (NMP): NMP employments steady nitroxide radicals to control the polymerization handle, driving the arrangement of monodisperse polymers.

2. Size-Exclusion Chromatography (SEC): SEC, also known as gel permeation chromatography (GPC), is a commonly used analytical technique to characterize the molecular weight distribution of polymers. It can also be used in preparative mode to fractionate polymers and isolate monodisperse fractions.

3. Fractionation Techniques: Fractionation methods help separate polymers based on their molecular weights, allowing for the isolation of monodisperse fractions.

Some fractionation techniques include:

a. Preparative SEC: SEC can be employed in a preparative mode to fractionate polymers based on their molecular weights. By collecting specific fractions, monodisperse polymer samples can be obtained.

b. Crystallization-Based Fractionation: Polymers can be fractionated based on their solubility and crystallization behavior. Fractionation techniques such as solvent fractionation and temperature fractionation can isolate monodisperse fractions.

4. Multi-Step Synthesis: Monodisperse polymers can be synthesized through multi-step processes involving selective reactions and purification steps. Sequential reactions and purification techniques such as selective precipitation or extraction can lead to monodisperse polymer samples.

5. Advanced Synthetic Strategies: Novel synthetic strategies, such as single-chain polymerization and living/controlled polymerization in continuous flow systems, are emerging to achieve monodisperse polymers. These techniques offer improved control over the polymerization process and enhance monodispersity.

It is imperative to note that the fabricating forms and strategies for monodisperse polymers can shift depending on the particular polymerization strategy, wanted properties, and aiming applications. Analysts and polymer researchers proceed to create inventive approaches to synthesize monodisperse polymers with exact control over atomic weights and properties.

Advantages and applications

Advantages of Monodisperse Polymers:

1. Precise Control: Monodisperse polymers offer precise control over the size, molecular weight, and architecture of polymer chains. This control allows for a systematic study of structure-property relationships and enables the tailored design of polymers with specific functionalities.

2. Predictable Properties: The uniformity in molecular weights and chain lengths of monodisperse polymers leads to more predictable and consistent material properties. This predictability simplifies characterization, processing, and performance optimization.

3. Improved Processability: Monodisperse polymers often exhibit improved processability compared to polydisperse polymers. Their uniformity enables more uniform melt flow behavior, enhanced mold filling, and better control over processing parameters.

4. Enhanced Performance: Monodisperse polymers can offer improved performance in specific applications. The uniformity of chain lengths can lead to enhanced mechanical properties, such as tensile strength, impact resistance, and elasticity. Additionally, it can improve thermal stability, electrical conductivity, and optical properties.

5. Tailored Functionality: Monodisperse polymers allow for precise tuning of chemical and physical properties to meet specific application requirements. By controlling the polymer structure and molecular weight, desired functionalities such as controlled drug release, surface modifications, and self-assembly behavior can be achieved.

Applications of Monodisperse Polymers:

1. Drug Delivery Systems: Monodisperse polymers are utilized in the development of controlled drug delivery systems. The precise control over molecular weight and structure enables the design of polymers with tailored drug release profiles, improving therapeutic efficacy and patient compliance.

2. Coatings and Adhesives: Monodisperse polymers find applications in the coatings and adhesives industries. They offer improved film-forming properties, uniform coating thickness, and enhanced adhesion, leading to high-quality and reliable coatings and adhesives.

3. Microelectronics: Monodisperse polymers play a vital role in microelectronics applications, such as lithography and photolithography processes. They are used as photoresists for patterning and defining fine features on semiconductor wafers.

4. Biomaterials: Monodisperse polymers are employed in the development of biomaterials for tissue engineering, regenerative medicine, and drug delivery. The precise control over polymer structure and properties allows for tailored biomaterials with desired biocompatibility, degradation rates, and mechanical properties.

5. Nanotechnology: Monodisperse polymers serve as building blocks in nanotechnology applications. They are utilized within the union of nanoparticles, nanocapsules, and nanocomposites with controlled sizes, shapes, and surface functionalities.

6. Specialty Materials: Monodisperse polymers find applications in specialty materials, including high-performance fibers, membranes, and advanced composites. Their uniformity and tailored properties contribute to enhanced mechanical strength, thermal stability, and chemical resistance in these materials.

The focal points of monodisperse polymers empower their utilization in a wide run of businesses, counting pharmaceuticals, coatings, gadgets, healthcare, and progressed materials. Their precise control over molecular weights and tailored properties offer opportunities for improved performance, functionality, and innovation in various applications.

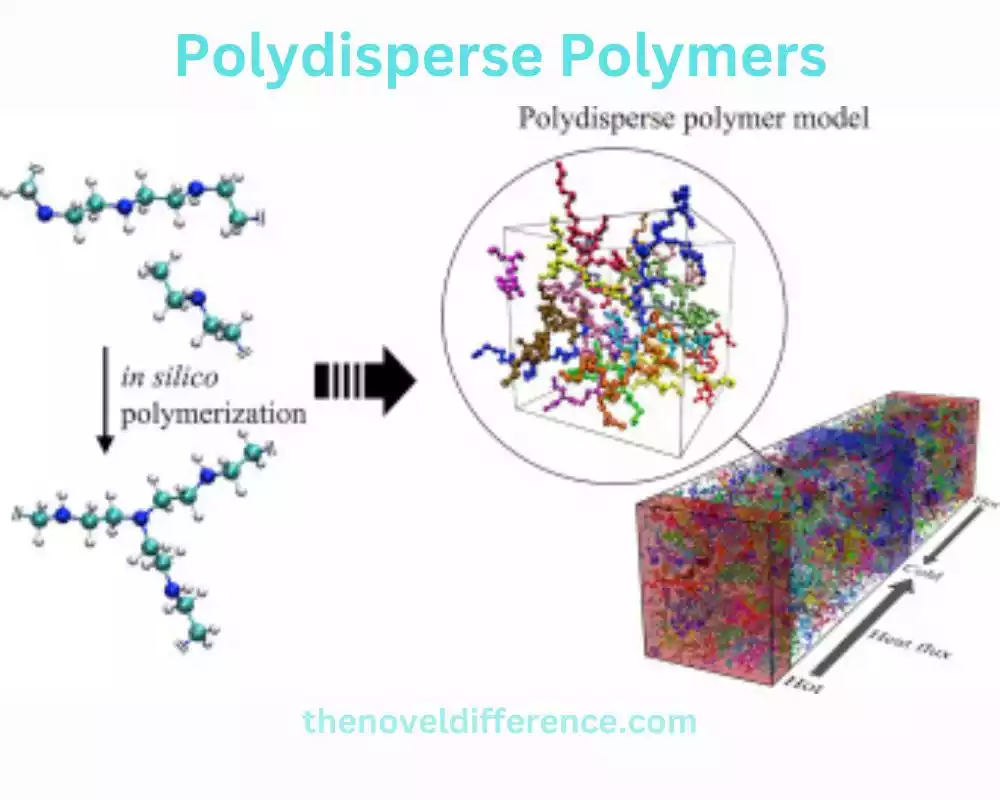

What are Polydisperse Polymers?

Polydisperse polymers are a class of polymers characterized by a wide range of molecular weights within a polymer sample. Not at all like monodisperse polymers, where the atomic weights of polymer chains are generally uniform, polydisperse polymers display noteworthy variety in chain lengths and atomic weights.

There is a distribution of different chain lengths, with some chains being shorter and others longer. This distribution leads to a broader range of molecular weights, resulting in a polydisperse molecular weight distribution.

Polydisperse polymers can arise due to various factors during the polymerization process, including variations in reaction conditions, kinetics, and termination mechanisms. It is challenging to achieve perfect uniformity in polymer chains, particularly in large-scale industrial polymerization processes.

The presence of a wide molecular weight distribution in polydisperse polymers can influence their properties and behavior. The properties of polydisperse polymers can vary across different molecular weight fractions, leading to a more diverse set of characteristics compared to monodisperse polymers.

It is imperative to note that polydispersity could be a continuum, and polymers can display distinctive degrees of polydispersity depending on the particular atomic weight conveyance. Some polymer samples may have a relatively narrow distribution, while others may have a broader range of molecular weights.

Polydisperse polymers discover applications in different businesses and areas, such as plastics, coatings, cement, materials, and bundling. Their availability in a wide range of molecular weights and chain lengths allows for cost-effective production and utilization in diverse applications.

Polydisperse polymers offer certain advantages and challenges compared to monodisperse polymers. While they may exhibit a broader range of properties and functionalities, the variations in molecular weights can lead to challenges in quality control, processing, and performance optimization.

Polydisperse polymers refer to polymers with a wide molecular weight distribution, characterized by variations in chain lengths and molecular weights. Their usage spans multiple industries, where the diversity in properties and availability in a range of molecular weights can be advantageous for specific applications.

Factors influencing polydispersity

Several factors can influence the polydispersity of polymers, leading to variations in molecular weights and chain lengths within a polymer sample.

Here are some of the key factors that contribute to the polydispersity of polymers:

1. Polymerization Conditions: The conditions beneath which polymerization takes put can altogether influence the polydispersity of polymers. Components such as temperature, weight, response time, and the nearness of catalysts or initiators can impact the polymerization energy and the coming about atomic weight dissemination.

2. Polymerization Mechanism: Different polymerization mechanisms can lead to varying degrees of polydispersity. For example, radical polymerization, which involves the initiation and propagation of free radicals, tends to result in broader molecular weight distributions compared to controlled or living polymerization methods that allow for more precise control over chain growth.

3. Reactant Ratios: The ratios of monomers, initiators, and other reactants used in the polymerization process can impact polydispersity. Imbalanced ratios or fluctuations in the reactant concentrations can lead to variations in chain lengths and molecular weights.

4. Chain Transfer Reactions: Chain transfer reactions during polymerization can influence polydispersity. Chain transfer agents can terminate the growing polymer chain and transfer the active polymer chain end to another species, affecting the chain length distribution. Higher levels of chain transfer reactions can result in increased polydispersity.

5. Termination Mechanisms: The termination mechanisms in polymerization can contribute to the polydispersity of polymers. For instance, in radical polymerization, termination can occur through combination reactions (two growing chains coming together) or disproportionation reactions (a growing chain transferring to a dormant chain). The relative rates of these termination reactions can affect the molecular weight distribution.

6. Chain Branching: The presence of chain branching or side reactions during polymerization can lead to increased polydispersity. Branching points introduce additional molecular weight variations within the polymer sample.

7. Reaction Kinetics: The kinetics of polymerization, including the rates of initiation, propagation, and termination, play a role in polydispersity. Fast initiation or termination rates compared to propagation rates can result in broader molecular weight distributions.

8. Polymerization Technique: The specific polymerization technique employed can influence the polydispersity. Different techniques, such as bulk polymerization, solution polymerization, emulsion polymerization, or suspension polymerization, can yield varying levels of polydispersity.

9. Monomer Characteristics: The nature of the monomers used in polymerization can impact the polydispersity. Monomers with different reactivity ratios or monomer impurities can introduce variations in the polymerization process and result in polydisperse polymers.

Controlling polydispersity is a significant challenge in polymer synthesis. Researchers employ various strategies, such as controlled/living polymerization techniques, precise control of reaction conditions, and the use of specific catalysts or initiators, to minimize polydispersity and achieve more monodisperse polymer samples.

Manufacturing processes and challenges

Manufacturing polydisperse polymers involves several processes and faces specific challenges.

Here are some common manufacturing processes and the associated challenges:

1. Bulk Polymerization: Monomers are polymerized in the absence of solvents. The challenge in this process is achieving consistent heat and mass transfer throughout the reaction mass, especially for large-scale production. Temperature control and maintaining uniformity throughout the reaction mixture can be challenging, leading to variations in polymerization kinetics and molecular weight distribution.

2. Solution Polymerization: Solution polymerization involves dissolving monomers in a solvent and initiating polymerization. Challenges in solution polymerization include the selection of an appropriate solvent, achieving good monomer solubility, and maintaining proper stirring or mixing to ensure uniform reaction conditions. Varying solubility and diffusion rates of monomers can contribute to polydispersity.

3. Emulsion Polymerization: Emulsion polymerization involves dispersing monomers in an aqueous medium with the aid of emulsifiers. The challenges lie in achieving stable and uniform droplet formation, controlling the size of emulsion droplets, and maintaining proper reaction conditions. Factors like the coalescence of droplets or monomer diffusion between droplets can lead to variations in molecular weights and polydispersity.

4. Suspension Polymerization: Suspension polymerization involves dispersing monomers as droplets in an inert liquid medium. The challenge is maintaining proper suspension stability and preventing the agglomeration of polymer particles. Variations in particle sizes and polymerization conditions can result in polydisperse products.

5. Chain-Growth Polymerization: Chain-growth polymerization techniques, such as radical polymerization, can be challenging to control in terms of molecular weight distribution. Rapid initiation and termination reactions, as well as chain transfer reactions, can introduce variations in chain lengths and molecular weights, leading to polydispersity.

6. Step-Growth Polymerization: Step-growth polymerization involves the reaction between monomers with two or more reactive groups. Challenges in step-growth polymerization include controlling the stoichiometry of reactants, achieving complete reactions between all reactive sites, and minimizing side reactions. Incomplete reactions or side reactions can contribute to polydispersity.

7. Purification and Characterization: Purifying polydisperse polymers to obtain a desired molecular weight fraction can be challenging. Techniques such as fractionation, chromatography, or selective precipitation may be employed, but achieving high purity and monodispersity can be time-consuming and costly. Additionally, characterizing polydisperse polymers accurately to determine the extent of polydispersity can be complex, requiring sophisticated analytical techniques.

8. Batch-to-Batch Variability: Reproducibility and consistency in polymerization processes from batch to batch can be challenging, leading to variations in molecular weight distribution. Small changes in reaction conditions, raw materials, or process parameters can influence the degree of polydispersity.

9. Scale-up Challenges: Transferring a polymerization process from laboratory-scale to commercial production can present challenges in maintaining consistent reaction conditions, heat transfer, and mixing at a larger scale. These scale-up challenges can contribute to variations in molecular weight distribution and polydispersity.

Controlling and reducing polydispersity in polymer manufacturing often requires optimization of reaction conditions, selection of appropriate polymerization techniques, and implementation of quality control measures. Continuous improvement and research efforts are focused on developing efficient processes and strategies to minimize polydispersity and produce polymers with desired molecular weight distributions.

Difference between Monodisperse and Polydisperse Polymers

Monodisperse Polymers:

1. Definition: Monodisperse polymers are characterized by a narrow molecular weight distribution, meaning that the polymer chains have a similar or uniform chain length and molecular weight.

2. Molecular Weight Distribution: Monodisperse polymers have a low polydispersity index (PDI), typically close to 1.0. The PDI is a measure of the width of the molecular weight distribution, with lower values indicating a narrower distribution.

3. Uniformity: Monodisperse polymers exhibit a high degree of uniformity in their properties, such as chain length, molecular weight, and size. The polymer chains are relatively homogeneous, which allows for precise control and predictable behavior.

4. Synthesis: Monodisperse polymers can be synthesized using controlled or living polymerization techniques. These techniques enable precise control over the polymerization process, resulting in uniform chain growth and narrow molecular weight distributions.

5. Properties: The uniformity in molecular weight and chain length gives monodisperse polymers consistent and well-defined properties. They exhibit more predictable behavior in terms of mechanical, thermal, and chemical properties compared to polydisperse polymers.

Polydisperse Polymers:

1. Definition: Polydisperse polymers have a wide molecular weight distribution, meaning that the polymer chains have a range of chain lengths and molecular weights within a polymer sample.

2. Molecular Weight Distribution: Polydisperse polymers have a high polydispersity index (PDI) greater than 1.0. The PDI reflects the broadness of the molecular weight distribution, with higher values indicating a wider distribution.

3. Variability: Polydisperse polymers exhibit a greater degree of variability in their properties due to the presence of different chain lengths and molecular weights. This variability can lead to a wider range of material properties and behaviors.

4. Synthesis: Polydisperse polymers can be obtained through conventional polymerization methods where control over the polymerization process is limited. In these processes, variations in reaction conditions and kinetics can lead to broader molecular weight distribution.

5. Properties: The variation in molecular weight and chain length within polydisperse polymers can result in a broader range of properties. Different molecular weight fractions within the sample may contribute to different mechanical, thermal, and chemical behaviors.

The key difference between monodisperse and polydisperse polymers lies in the uniformity or variability of their molecular weight distribution. Monodisperse polymers have a contract dissemination with uniform properties, whereas polydisperse polymers have a more extensive dispersion with more assorted properties. The choice between monodisperse and polydisperse polymers depends on the specific application requirements and desired control over the material’s properties.

Future Trends and Developments

The field of polymer science and design is always advancing, and a few future patterns and advancements are forming the understanding, union, and applications of both monodisperse and polydisperse polymers.

Here are some prominent trends and developments:

1. Controlled Polymerization Techniques: Advancements in controlled or living polymerization techniques are expected to continue, enabling the synthesis of monodisperse polymers with precise control over molecular weight, chain length, and architecture. Techniques such as atom transfer radical polymerization (ATRP), reversible addition-fragmentation chain transfer (RAFT) polymerization, and ring-opening metathesis polymerization (ROMP) offer improved control and may lead to the development of new monodisperse polymers.

2. Functional Polymer Design: The future of polymer science lies in the development of functional polymers with tailored properties for specific applications. This includes designing polymers with controlled surface properties, self-healing capabilities, stimuli-responsive behavior, and advanced functional groups. The integration of monodisperse or polydisperse polymers with other materials and nanotechnology is expected to empower imaginative applications in ranges such as hardware, biomedical building, and vitality capacity.

3. Advanced Characterization Techniques: Advances in characterization techniques will play a crucial role in understanding and characterizing the structure and properties of monodisperse and polydisperse polymers. Strategies such as high-resolution microscopy, diffusing strategies (e.g., small-angle X-ray scrambling, energetic light scrambling), and spectroscopic strategies (e.g., NMR, FTIR) will proceed to advance, giving nitty gritty bits of knowledge into the atomic design, flow, and intelligent of polymers.

4. Multiscale Modeling and Simulation: Computational modeling and simulation approaches will become increasingly important in polymer science and engineering. These methods will allow researchers to predict and optimize the properties and behavior of monodisperse and polydisperse polymers, guiding the design of new materials with desired functionalities. Multiscale modeling, encompassing quantum mechanics, molecular dynamics, and continuum models, will aid in understanding polymer behavior at various lengths and time scales.

5. Sustainable and Bio-Based Polymers: With a growing emphasis on sustainability and environmental concerns, the development of sustainable polymers and bio-based alternatives will gain momentum. Researchers are exploring renewable feedstocks, green chemistry methods, and biodegradable polymers to reduce the environmental impact of polymer synthesis and end-of-life disposal.

6. Additive Manufacturing and 3D Printing: Additive manufacturing techniques, including 3D printing, offer new opportunities for polymer fabrication. Advances in 3D printing technologies and materials will allow for the precise printing of complex structures using monodisperse or polydisperse polymers. This enables the customization and rapid prototyping of functional components and devices.

7. Hybrid and Composite Materials: Hybrid and composite materials combining polymers with other materials, such as nanoparticles, fibers, or biomaterials, will continue to be explored. These combinations offer upgraded properties, such as progressed mechanical quality, conductivity, or biocompatibility, and extend the extent of applications for both monodisperse and polydisperse polymers.

8. Biomedical and Biotechnological Applications: Polymers play an imperative part in biomedical and biotechnological areas, counting sedate conveyance frameworks, tissue designing frameworks, biosensors, and biocompatible materials. Ongoing research aims to develop monodisperse and polydisperse polymers with precise functionalities to address specific medical and biotechnological challenges, such as targeted drug release, tissue regeneration, and biosensing.

These future patterns and improvements in polymer science and building hold extraordinary potential for progressing the understanding, union, and applications of both monodisperse and polydisperse polymers, empowering the advancement of inventive materials with custom-made properties for a wide run of businesses and applications.

Conclusion

Understanding the difference between monodisperse and polydisperse polymers is crucial for tailoring polymer properties to specific applications. While monodisperse polymers offer precise control and consistency, polydisperse polymers embrace variability and flexibility.

The choice between the two depends on the desired properties, application requirements, and synthesis complexity. Both types have their unique advantages and can be employed in various industries to achieve specific material characteristics.