When it comes to sonicating samples, two common devices are often used the Probe Sonicator and Bath Sonicator. Both these instruments utilize ultrasonic energy to disrupt and disperse particles in a sample. They have distinct differences in terms of operation, applications, and efficiency. We will delve into the key dissimilarities between a probe sonicator and a bath sonicator, highlighting their unique features and discussing their respective pros and cons.

Importance of sonication in various scientific and industrial applications

Sonication, a procedure that utilizes high-frequency sound waves, plays a crucial part in a wide run of logical and mechanical applications. Its importance stems from its ability to effectively manipulate and process various materials at the molecular level. Sonication is indispensable in fields such as biology, chemistry, and physics. It is extensively employed in sample preparation, particularly for homogenization and cell disruption, enabling the extraction of proteins, DNA, and other cellular components.

Sonication also aids in particle size reduction, emulsification, and dispersion, facilitating thorough mixing and enhancing reaction kinetics in chemical synthesis. Sonication finds applications in diverse sectors. For instance, in pharmaceutical manufacturing, sonication is utilized for drug formulation and encapsulation, enabling the production of stable and uniform drug delivery systems. Sonication assists in the extraction of bioactive compounds from plant materials, enhancing flavors, and improving the overall quality of food products. Additionally, sonication is employed for degassing liquids, cleaning delicate surfaces, and assisting in various quality control processes.

The significance of sonication lies in its ability to efficiently disrupt cellular structures, disperse particles, and promote chemical reactions. By harnessing ultrasonic waves, sonication provides a powerful and versatile tool for researchers and industries to achieve desired outcomes in their scientific investigations and manufacturing processes. The precise control over sonication parameters, such as intensity and duration, further enhances its utility, allowing for tailored applications specific to the needs of each field.

Definition of Probe Sonicator and Bath Sonicator

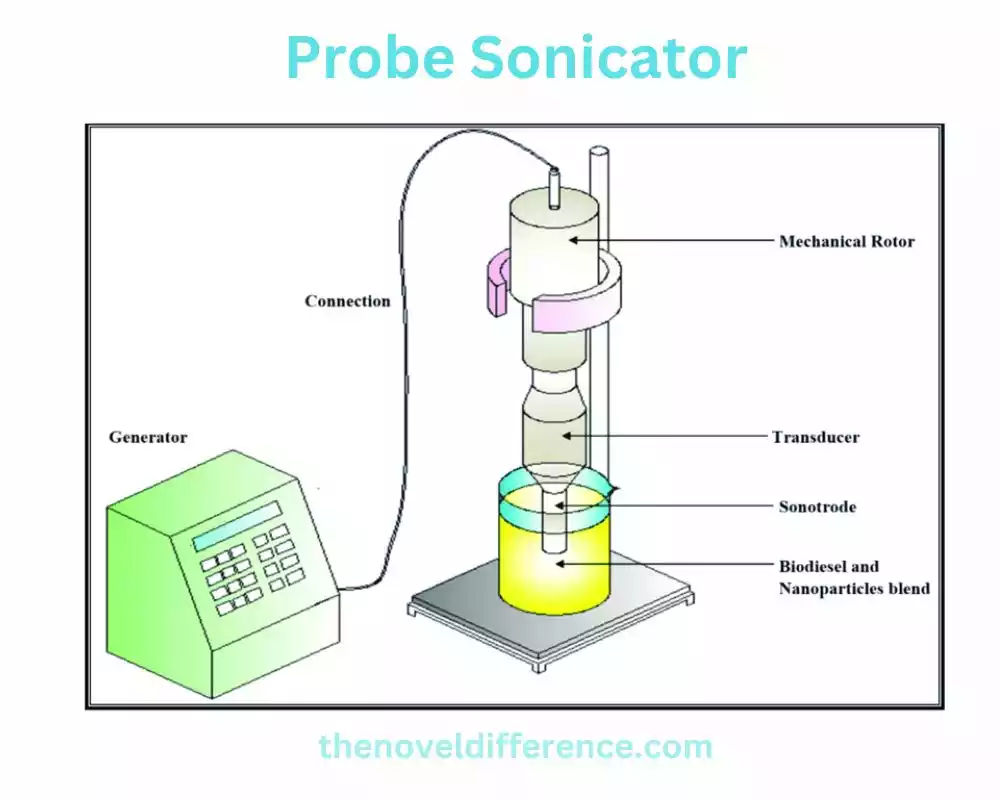

Probe Sonicator: A probe sonicator, also known as an ultrasonic disruptor or a tip sonicator, is a handheld device used in scientific and industrial applications for various processing purposes. It operates based on the principle of ultrasonic waves generated by a vibrating probe. The probe, immersed in the sample, creates high-frequency sound waves that induce cavitation and mechanical shear forces. This results in the disruption of cells, homogenization of samples, and dispersion of particles. Probe sonicators offer precise control over sonication parameters such as intensity, pulse duration, and duty cycle, allowing researchers to optimize the desired outcome for their specific application.

Bath Sonicator: A bath sonicator, also referred to as an ultrasonic water bath, is a benchtop device used for sonication applications. It utilizes a water bath as the medium for sonicating samples. Inside the water shower, one or more ultrasonic transducers emanate high-frequency sound waves that engender through the fluid. The sound waves create alternating cycles of compression and rarefaction, resulting in cavitation and the generation of acoustic streaming. This leads to the disruption of cells, dispersion of particles, and cleaning or degassing of materials. Bath sonicators are often suitable for processing larger sample volumes or multiple samples simultaneously. They generally offer less precise control over sonication parameters compared to probe sonicators.

What is Probe Sonicator?

A probe sonicator, also known as an ultrasonic disruptor or a tip sonicator, is a specialized device used in scientific and industrial settings for various processing applications. It operates on the principle of ultrasonic waves generated by a vibrating probe. The probe, typically made of titanium or other suitable materials, is immersed directly into the sample being processed.

The probe sonicator converts electrical energy into mechanical vibrations at a high frequency, typically in the range of 20 kHz to 70 kHz. These vibrations are then transmitted through the probe tip into the sample, creating intense ultrasonic waves. The ultrasonic waves cause cavitation, which refers to the rapid formation and collapse of small bubbles in the sample.

During cavitation, the bubbles implode, generating localized shock waves and intense shear forces. This phenomenon leads to the disruption of cellular structures, homogenization of samples, and dispersion of particles. Probe sonicators are widely used for applications such as cell lysis, emulsification, nanoparticle synthesis, and dispersion of materials.

One of the key advantages of probe sonicators is their precise control over sonication parameters. Users can adjust the intensity, pulse duration, and duty cycle to achieve specific processing goals. This control allows researchers and technicians to optimize their sonication conditions for desired outcomes while minimizing potential damage to sensitive samples.

Probe sonicators are commonly employed in various fields, including biology, chemistry, pharmaceuticals, nanotechnology, and materials science. They provide a versatile and efficient means of sample processing, enabling researchers and industrial professionals to achieve consistent and reproducible results in their applications.

Applications and benefits

Probe sonicators have a wide range of applications and offer several benefits in scientific and industrial settings.

Here are some common applications and benefits of probe sonicators:

1. Sample Homogenization and Cell Disruption: Probe sonicators are widely used for the homogenization and disruption of biological samples, such as cells and tissues. They successfully break down cellular structures, discharging proteins, nucleic acids, and other intracellular components. This enables researchers to extract and study specific molecules for various biological and biomedical research purposes.

2. Emulsification and Particle Size Reduction: Probe sonicators are effective in emulsifying immiscible liquids and reducing the particle size of suspensions. By applying ultrasonic energy, they facilitate the creation of stable emulsions and enable the production of uniform nanoparticle dispersions. This is valuable in areas like pharmaceuticals, food processing, and cosmetics, where particle size control is crucial for product stability and performance.

3. Nanoparticle Synthesis: Probe sonicators play a vital role in the synthesis of nanoparticles, such as metal nanoparticles or liposomes. The intense cavitation generated by the sonicator promotes nucleation and growth, resulting in the formation of well-dispersed nanoparticles with controlled sizes and properties. These nanoparticles discover applications in different areas, counting catalysis, sedate conveyance, and nanomedicine.

4. Disintegration and Dissolution: Probe sonicators aid in disintegrating and dissolving solid materials, facilitating their further processing or analysis. They are used to break down agglomerates, release active ingredients, and enhance the solubility of compounds. This is particularly beneficial in areas such as pharmaceutical development, where efficient dissolution is crucial for drug formulation and bioavailability.

5. Cleaning and Degassing: Probe sonicators are effective tools for cleaning delicate surfaces and removing contaminants. The ultrasonic waves create microscopic bubbles that agitate the cleaning solution, dislodging particles and contaminants from surfaces. Additionally, probe sonicators are used for degassing liquids, removing dissolved gases, and improving the quality of samples or materials.

The benefits of using probe sonicators include:

• Precise Control: Probe sonicators offer precise control over sonication parameters, allowing users to optimize intensity, pulse duration, and duty cycle for specific applications. This control ensures reproducibility and allows customization based on sample characteristics and processing goals.

• Scalability: Probe sonicators can be used for small sample volumes as well as larger volumes, making them versatile for both research laboratories and industrial-scale operations.

• Time Efficiency: Probe sonicators provide rapid processing times, allowing for quick sample preparation and reducing overall processing time in various applications.

• Versatility: Probe sonicators can handle a wide range of sample types, including cells, tissues, suspensions, and emulsions. They are adaptable to different research areas and industrial processes, making them versatile tools in various fields.

• Minimal Sample Contamination: Since probe sonicators operate with the probe tip directly immersed in the sample, there is minimal risk of cross-contamination between samples.

The applications and benefits of probe sonicators make them indispensable tools for sample preparation, particle manipulation, and various processing needs in scientific research and industrial production.

Limitations

While probe sonicators offer numerous advantages, it is important to consider their limitations as well.

Here are some common limitations associated with probe sonicators:

1. Sample Volume Restrictions: Probe sonicators are typically designed for processing smaller sample volumes. The size of the vibrating probe limits the sample volume that can be effectively sonicated. Processing larger volumes may require multiple sonication cycles or the use of alternative equipment.

2. Potential Heat Generation: Prolonged sonication with probe sonicators can generate heat due to the energy transfer from the vibrating probe to the sample. Heat generation can impact the stability and integrity of sensitive samples, such as proteins or heat-sensitive compounds. Careful monitoring and optimization of sonication parameters, such as intensity and duration, are necessary to minimize heat-related effects.

3. Limited Coverage Area: The sonication effect of a probe sonicator is localized around the tip of the vibrating probe. This means that only a specific area of the sample directly in contact with the probe will experience the highest intensity of sonication. It is important to consider the sample container’s geometry and ensure adequate mixing or movement during sonication to achieve uniform results.

4. Noise and Vibration: Probe sonicators can generate noise and vibrations during operation. While modern sonicator models are designed to minimize these effects, prolonged or intense use may still result in noise or vibrations that could potentially disrupt laboratory operations or sensitive equipment nearby.

5. Operator Skill and Training: Effective use of probe sonicators requires proper operator training and skill. Understanding the instrument’s capabilities, optimizing sonication parameters, and avoiding potential pitfalls is crucial to achieving desired results. Inexperienced or improper use of probe sonicators may lead to inconsistent outcomes or potential sample damage.

6. Limited Control over Frequency Range: Probe sonicators generally operate within a specific frequency range (e.g., 20 kHz to 70 kHz). While this range covers many applications, there may be instances where a specific frequency outside the range is required for optimal results. In such cases, alternative sonication methods or specialized equipment may be necessary.

It is important to consider these limitations and evaluate whether probe sonicators are suitable for the specific requirements of the application at hand. In some cases, alternative sonication methods, such as bath sonicators or other specialized equipment, may offer advantages or overcome certain limitations associated with probe sonicators.

What is Bath Sonicator?

A bath sonicator, also known as an ultrasonic water bath, is a type of sonication device used in scientific and industrial settings for various processing applications. It consists of a water bath that serves as a medium for sonicating samples. Bath sonicators are designed to accommodate multiple samples simultaneously, making them suitable for processing larger volumes or conducting batch experiments.

The working principle of a bath sonicator involves the use of ultrasonic transducers immersed in the water bath. These transducers emanate high-frequency sound waves, ordinarily within the extent of 20 kHz to 40 kHz, into the fluid medium. The sound waves propagate through the water, creating cycles of compression and rarefaction.

Amid the compression stage, the sound waves cause the fluid atoms to come closer together, whereas, amid the rarefaction stage, the atoms move separated. This cyclic compression and rarefaction create regions of low pressure and high pressure within the liquid, resulting in the formation and collapse of small bubbles, known as cavitation.

The cavitation phenomenon generated by the bath sonicator leads to various effects, including the release of energy in the form of shock waves and the generation of acoustic streaming. The shock waves can disrupt cells, break down agglomerates, or promote chemical reactions, depending on the specific application. Acoustic streaming refers to the movement of liquid caused by the sound wave-induced oscillation of the bubbles, which aids in mixing and enhancing the overall processing efficiency.

Bath sonicators are commonly used in applications such as sample cleaning, degassing, dispersion, and particle size reduction. They are particularly useful for cleaning delicate items or parts, such as laboratory glassware or small components, by agitating the cleaning solution and dislodging contaminants. Bath sonicators can also assist in degassing liquids by removing dissolved gases, which is important in certain analytical techniques or manufacturing processes.

Bath sonicators are employed for dispersing nanoparticles, mixing and homogenizing liquid formulations, and facilitating enzymatic reactions. They offer the advantage of processing multiple samples simultaneously, saving time and improving efficiency compared to probe sonicators. Bath sonicators generally provide less precise control over sonication parameters, such as intensity and duration, compared to their probe counterparts.

Bath sonicators are versatile tools for various processing applications, offering the convenience of batch processing and the ability to handle larger volumes or multiple samples simultaneously.

Applications and benefits

Bath sonicators have a wide range of applications and offer several benefits in scientific and industrial settings.

Here are some common applications and benefits of bath sonicators:

1. Sample Cleaning and Degassing: Bath sonicators are widely used for cleaning delicate items and parts, such as laboratory glassware, jewelry, or electronic components. The cavitation generated by the sonicator helps in dislodging contaminants from the surfaces, providing thorough and efficient cleaning. Additionally, bath sonicators are effective in degassing liquids by removing dissolved gases, ensuring high-quality samples or materials for subsequent processes.

2. Dispersion and Emulsification: Bath sonicators are utilized for dispersing solid particles or creating stable emulsions in liquid media. The cavitation and acoustic streaming produced by the sonicator facilitate the breakup of agglomerates and promote uniform dispersion throughout the liquid. This is particularly useful in applications such as nanoparticle dispersion, ink formulation, and preparation of stable emulsions for cosmetics or food products.

3. Particle Size Reduction: Bath sonicators can assist in reducing the particle size of suspensions or emulsions. By subjecting the samples to intense ultrasonic energy, the sonicator breaks down larger particles into smaller sizes, resulting in improved stability, enhanced bioavailability, or altered material properties. Typically important in areas like pharmaceuticals, nanotechnology, and materials science.

4. Material Extraction and Processing: Bath sonicators find applications in extracting compounds from natural materials, such as plant extracts or herbal products. The ultrasonic waves facilitate the release of bioactive compounds, flavors, or fragrances from the source material, enhancing extraction efficiency. Additionally, bath sonicators are employed in processes like degassing casting resins or improving the dispersibility of pigments in paints or coatings.

5. Quality Control and Analysis: Bath sonicators play a role in various quality control processes and analytical techniques. They aid in sample preparation for spectroscopic analysis, dissolution testing, or particle size characterization. By sonicat<|endoftext|>

Limitations

1. Language barrier: Language limitations can be a significant barrier when it comes to communication and understanding between people from different linguistic backgrounds. It can hinder effective communication and lead to misunderstandings.

2. Cultural differences: Cultural limitations can arise from different cultural norms, values, and beliefs. These differences can impact communication and understanding, making it challenging to establish common ground.

3. Physical distance: Physical limitations can make it difficult to establish and maintain relationships, particularly in long-distance situations. Physical distance can also hinder the exchange of ideas and limit collaboration opportunities.

4. Access to technology: Technological limitations can impact communication and access to information. Limited access to technology or unreliable internet connections can hinder effective communication and limit opportunities for knowledge sharing.

5. Time constraints: Time limitations can make it difficult to establish and maintain relationships, particularly in fast-paced environments. Limited time can also hinder effective communication and decision-making processes.

6. Personal biases and prejudices: Personal limitations can arise from biases and prejudices, which can hinder effective communication and understanding. These biases can limit opportunities for collaboration and hinder the formation of meaningful relationships.

7. Lack of resources: Limited resources can hinder effective communication and limit opportunities for collaboration. Need subsidizing or getting to fundamental gear can ruin the trade of data and constrain the capacity to work together on ventures.

8. Legal and regulatory limitations: Legal and regulatory limitations can impact communication and collaboration, particularly in cross-border situations. Compliance with different legal frameworks can create challenges and limitations in terms of sharing information and working together.

9. Organizational structures: Organizational limitations can arise from hierarchical structures, bureaucracy, and siloed departments. These limitations can hinder effective communication and collaboration within and between organizations.

10. Individual limitations: Individual limitations can include factors such as personal insecurities, lack of confidence, or limited knowledge and skills. These limitations can impact communication and collaboration, making it difficult to establish and maintain relationships.

Differences between probe and bath sonicators

Probe Sonicator:

1. Design: A probe sonicator consists of a handheld probe that is immersed directly into the sample to perform sonication. The probe is connected to an ultrasonic generator that produces high-frequency sound waves.

2. Sonication method: High-frequency sound waves are generated by the probe and transmitted directly into the sample. The probe is inserted into the liquid, and the ultrasonic waves create cavitation bubbles, leading to the disruption and breakage of particles.

3. Sample volume: Probe sonicators are ideal for processing small to medium-sized sample volumes, typically ranging from a few milliliters to a few liters. They are suitable for homogenizing, emulsifying, and dispersing samples.

4. Control and flexibility: Probe sonicators offer precise control over sonication parameters such as intensity, amplitude, and duration. The operator has direct control over the position and movement of the probe, allowing for targeted and localized sonication.

Bath Sonicator:

1. Design: A bath sonicator consists of a water bath tank that is filled with a liquid medium, usually water or a suitable solvent. The sample is placed in a container or tube that is immersed in the bath.

2. Sonication method: Ultrasonic waves are generated by transducers that are attached to the bottom or sides of the water bath tank. The waves propagate through the liquid medium, creating cavitation bubbles that induce sample disruption.

3. Sample volume: Bath sonicators are suitable for processing larger sample volumes, typically ranging from a few liters to several liters. They are commonly used for cleaning, degassing, and dispersion applications.

4. Control and flexibility: Bath sonicators offer less precise control over sonication parameters compared to probe sonicators. The intensity and amplitude of sonication are influenced by factors such as bath temperature, liquid medium, and sample container position within the bath.

Probe sonicators are used for smaller sample volumes and provide direct and precise control over sonication parameters, while bath sonicators are suitable for larger volumes but offer less control and flexibility in sonication conditions.

Comparison and Contrast

Comparison:

1. Both probe and bath sonicators utilize ultrasonic waves to disrupt and break down samples.

2. Both probe and bath sonicators are commonly used in scientific research and industrial applications.

3. Both probe and bath sonicators can be used for homogenization, emulsification, dispersion, cleaning, and degassing of samples.

Contrast:

1. Design: Probe sonicators consist of a handheld probe that is directly inserted into the sample, while bath sonicators have a water bath tank where the sample container is immersed.

2. Sample Volume: Probe sonicators are suitable for small to medium-sized sample volumes, while bath sonicators are used for larger volumes.

3. Control and Flexibility: Probe sonicators offer precise control over sonication parameters, such as intensity and duration, while bath sonicators provide less control due to factors like bath temperature and sample container position.

4. Localization: Probe sonicators allow for targeted and localized sonication, while bath sonicators provide more general and uniform sonication throughout the entire sample.

5. Versatility: Probe sonicators are more versatile and can be used for various applications, while bath sonicators are commonly used for cleaning and degassing applications.

The choice between probe and bath sonicators depends on the specific requirements of the application, including sample volume, level of control needed, and the desired outcome.

Conclusion

Probe sonicator and bath sonicator are two distinct types of ultrasonic devices used for sample sonication. Probe sonicators offer precise and localized treatment, making them ideal for small-volume samples and specific applications.

Bath sonicators provide efficient bulk processing, allowing for the simultaneous sonication of multiple samples. The choice between these devices depends on factors such as sample volume, processing control, and application requirements. By understanding the differences between Probe sonicator and bath sonicator, you can make an informed decision to meet your experimental needs.